On these solid foundations, RAVNI Technologies has not ceased to provide innovative, reliable and ergonomic solutions that make machine operation even easier and with a very fast return on investment.

Some examples of which Ravni Technologies has been a forerunner and which still distinguishes it today from its competitors:

- Quick tool changes, (pre-set rotors of rotary blockers, indexed locking jaws, preset support wheel, mechanical memories of roller straighteners, …)

- Highly modular design for cost optimization, a much simpler machine operation and a very significant reduction in maintenance. Ravni Technologies was the first to equip each module (feed-straightening-cutting) of its own engine.

- Release of the rollers during the cut.

- Ravni Technologies is the only manufacturer to have developed a specific range dedicated to the shaped wire.

- Design and manufacture of a first slot screen machine, in the 1980s. Today the expertise of Ravni Technologies allows to obtain 25μ slots.

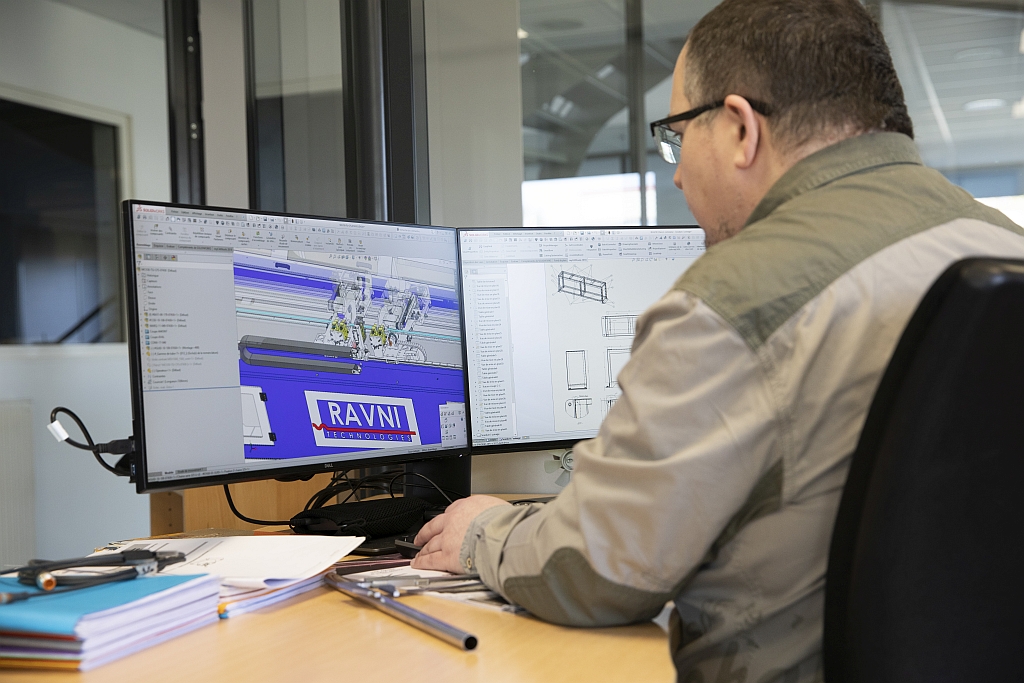

Customized machines

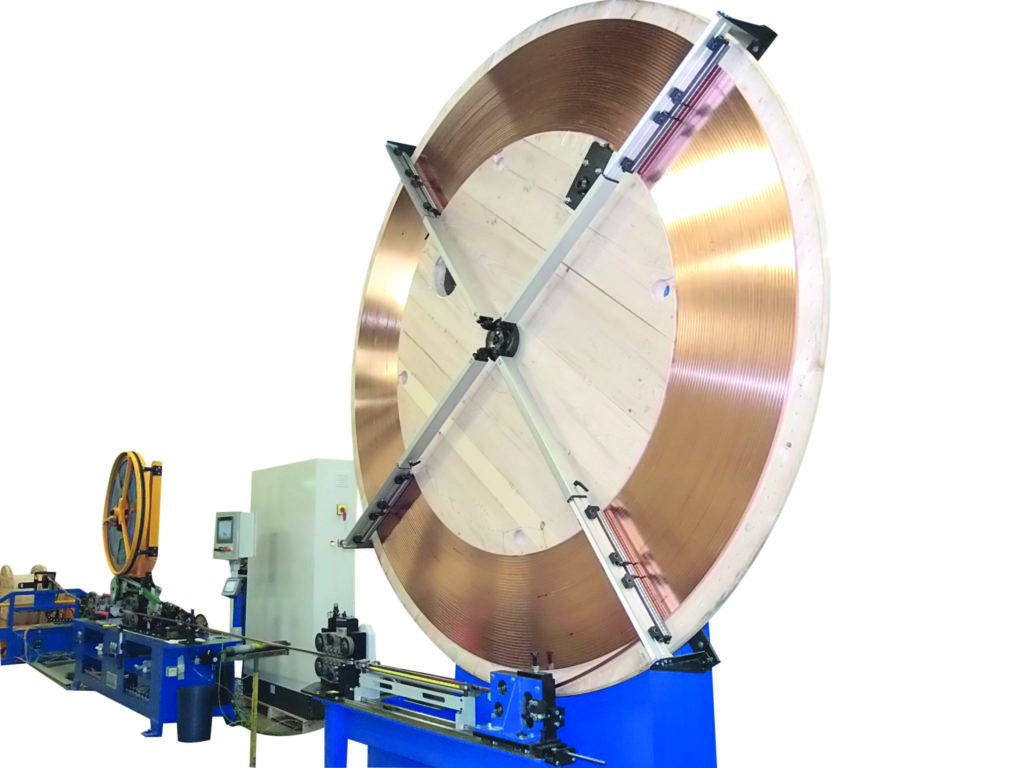

Faithful to our core business of unwinding, straightening, cutting for wire, tube and profiles, we have made a point of honor to offer our customers comprehensive and tailor-made solutions by developing end machining machines, bending, stamping, welding and other special decoilers, bar distributors, automatic crating systems, etc.). This ability to innovate and personalize machines has made it possible, in particular, to work in partnership with CNRS Grenoble in 2017 to produce a superconducting assembling line on a copper profile and a flat spiral winding.

Any questions?

Any questions?